1-877-795-2278 | info@aircraftspruce.ca

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

THE AVIATION SUPERSTORE FOR ALL YOUR AIRCRAFT & PILOT NEEDS | 877-795-2278

Ivoprop Electric In-Flight Adjustable Magnum Model

Select # of Blades:

2 Blade3 Blade6 BladeOverview

|

The ability to change the pitch in flight is as significant for the airplane pilot as for the driver of a car to shift gears in the transmission. This results in substantial savings in fuel, engine wear and noise.

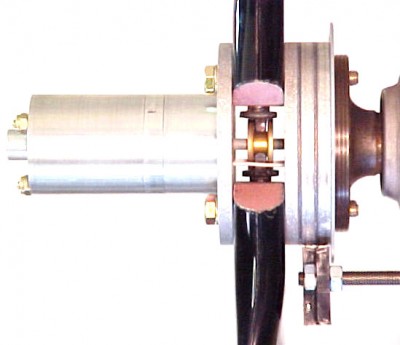

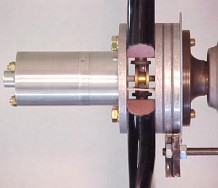

Pilot controls the pitch through the toggle switch mounted in the cockpit. Pressing the toggle switch one way sends electric current through the graphite brushes to the slip rings and finally to the electric motor. Depressing the toggle switch the other way-reverses the polarity of the current and the rotation of the electric motor. The pitch change operation is similar to the power windows in an automobile. As long as you hold the switch in one direction the pitch changes in that direction and you observe the result on your RPM meter. Torque from the electric motor is multiplied in a planetary gear drive which turns the lead screw. Lead screw is supported by a thrust bearing and converts it's rotary motion into axial movement of the spool. The spool is linked to the supercams which turn the torsional rods. Torsional rods transmit the movement from the center of the prop to the outside section of the blade. This causes the blade to twist therefore changing the pitch in the same manner as the ground adjustable system. Movement of the spool can be restricted each way by inserting washers on the lead screw. This limits maximum and minimum pitch and prevents engine over-revving. Can be adapted to other engines. Ground adjustable prop can be converted to the In flight Adjustable system by means of a retrofit kit. In-flight adjustable hub comes assembled with instructions on how to use it. |

Features

- In flight or ground adjustable pitch

- For engines up to 700 H.P.

- Carbon/graphite fiber/composite

- All blades protected by stainless steel leading edges

- Light, strong, efficient, quiet, smooth

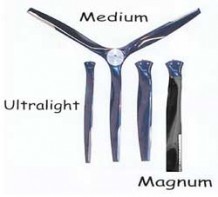

- Size between Ultralight and Magnum

- Good for fast planes - scaled down Magnum shape

- Unique pitch adjustment design no protractor or pitch blocks required for Ground adjustment

- Low drag hub

- Beautiful high gloss black gelkote finish

- Easily and quickly converts from 3 blade into 2 blade configuration - giving you a spare blade

- Blades individually replaceable

Specifications

- For engines up to 700 H.P.

- 30"- 90" or 45" to 105" pitch range

- 58"-76" diameter

Documents

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Aircraft Spruce Canada

Aircraft Spruce Canada