Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

West System 300 Mini Pump Kit

MFR Model# 3405669

Overview

|

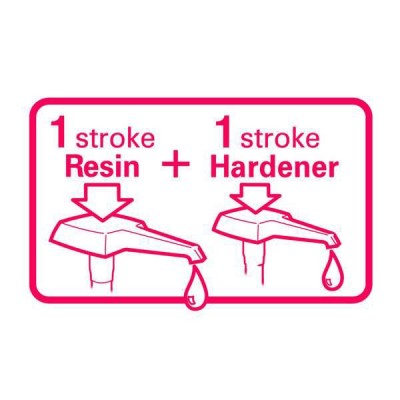

300 Mini Pumps are designed for convenient and accurate metering of group sizes A, B and C WEST SYSTEM resins and hardeners. The set contains one resin pump and two hardener pumps. Pumps mount directly onto the resin and hardener containers and eliminate the mess involved with measuring by weight or volume.

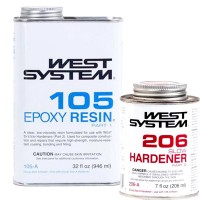

300 Mini Pumps are calibrated to deliver the proper working ratio with one full pump stroke of resin for each one full pump stroke of hardener. 105/205 and 105/206 pumps deliver approximately 0.8 fluid ounces of resin/hardener with one full stroke of each pump. 105/207 and 105/209 pumps deliver approximately 0.9 fluid ounces of resin/hardener with one full stroke of each pump. Made of durable polypropylene, the pumps give years of dependable service. As packaged, the pumps are ready to install on Group Size B containers. A package of extension tubes for Group Size A containers is included with the set. Group Size C extension tubes are included in the 105-C Resin and in the 207-SC or 209-SC packages. |

Specifications

- 300 Mini Pump Kit for group size A, B or C

Videos

Reviews

arrived on time in good condition

West System 300 Ratio Pumps

West System 300 Ratio Pumps

Great for pumping reducer rather than pouring and spilling so much of it.

West System 300 Ratio Pumps

Worked as described.

West System 300 Ratio Pumps

The convenient West pumps can be used with other brands of epoxy as follows. I made measurements that showed that the West large pump delivers about 0.66 fl. oz. of resin per full stroke. The 207/209 hardener pump delivers about 0.22 fl. oz. per full stroke mixing this with the resin squirt yields a total of about 0.88 fl. oz., with a resin to hardener volume ratio of about 2.95. The 205/206 pump delivers about 0.12 fl. oz. of hardener per full stroke mixing this with the resin squirt yields a total of about 0.78 fl. oz., with a resin to hardener volume ratio of about 5.45. With this information, it is possible to figure how to use the West pumps with other brands of epoxy. For example, the recommended EZ Poxy resin/hardener volume ratio is 100/47 = 2.13. Two strokes of the resin pump and three strokes of the hardener pump yields a mix ratio of 1.32/0.66= 2.00, which is close to the recommended 2.13. If you want to be closer, use 2.1 strokes of the resin pump to 3 strokes of the hardener pump, which yields a volume ratio of 1.39/0.66= 2.11.

Works great. Nice not having to seal it after use

West System 300 Ratio Pumps

I received exactly what I ordered, everything worked perfectly, shipping price is on the high side, however it got to me in three days, makes it worth every penny.

West System 300 Ratio Pumps

West System 300 Ratio Pumps

If you get the West products, you have to get these. Mixing is perfect, no mess, no worry.

Work as advertised. I purchased the small kit and the slip in adapter tips made for a perfect fit. The pumps work as advertised. Not over priced (fair). Very happy with the purchase.

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

This kit comes with instructions, but in short, this kit is designed to be used with 105 resin, and several hardeners. The pumps are identified so the correct pump is used with the hardener.

The pumps are designed for specific numbers of the sytem and are not interchangeable due to the size of the lids and ratios. The shortest of the pumps fits the 207 and 209 hardeners. The middle size fits the 205 and 206 hardeners. And the longest pump fits the 105 resin.

This will not work if you are going by ratio but for dispensing ONLY, one of the pumps will fit on the EZ Poxy gallon container only.

They can be left on during storage. If they have been stored for a long time, you would need to clean and prime them. The instructions don't have exact times due to differing storage conditions.

Aircraft Spruce Canada

Aircraft Spruce Canada