Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

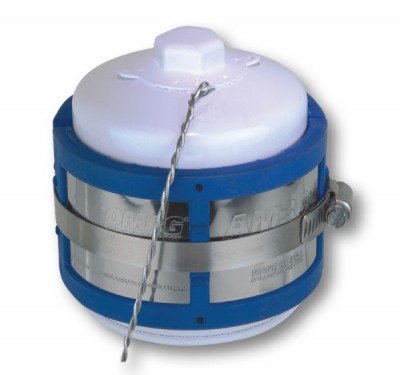

AM365 3.5 Aeromag Oil Filter Magnet

MFR Model# AM365

| Description | Part No. |

|---|---|

| AM365 (Single) Fits oil filter diameters from 3.6 in. (91mm) to 4.2 in. (107mm). For most Continental and Lycoming engines with at least a 3.625 in. diameter oil filter | 08-01088 |

Overview

|

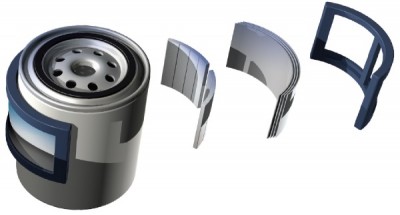

AeroMag® Maximum Engine Protection…In a Snap! If lubrication were perfect, nothing would ever wear out. Note: Sold as a single unit, however to gain maximum results purchase as a set of two (one on each side as shown in images). Within the tight clearances of today’s aircraft engines, normal wear generates tiny steel particles that are carried away in your oil. These particles are so small they will pass right through an normal oil filter. When the oil circulates back into the engine, these same particles are carried into every lubricated space where they can cause three body abrasive wear. This particle-laden oil will continue to lubricate, but it will also cause an exponential increase in wear while it circulates. The longer the oil is used, the greater the wear, the shorter the life, and the lower the reliability. AeroMag® extracts normal, wear-causing steel particles from your oil with its powerful, focused, magnetic field technology. These particles are permanently trapped on the inside wall of the filter and are thrown away when the filter is changed. Slide the AeroMag® off the old filter, snap it onto a new one and it goes right back to work protecting your engine. Snap On • Slide Off • Reuse Little Known Lubrication Facts:

1. Powerful, heat-resistant neodymium alloy magnets are engineered to focus a magnetic field inside your filter. Specifically formulated to remain effective in the most extreme environments, these magnets are guaranteed to remove particles from oil operating at up to 300ºF. (Most magnets start losing magnetism at 180ºF.) 2. Patented Fluxcon™ shielding technology stops magnetic flux which could affect electronic components. Not even a paper clip will stick to the outside of an AeroMag®. FluxCon™ shielding also redirects a portion of that magnetic power back into the filter to increase filtration efficiency. 3. Rugged flexible frame encases and protects the elements of an AeroMag® while providing enough flexibility to fit a range of filter diameters. The proprietary design and materials are rated for temperatures from -40ºF to +300ºF. |

Documents

Videos

Reviews

Great Product! Keep those engines running!

AM365 3.5 Aeromag Oil Filter Magnet

Have been using AerMag magnet bands on three aircraft for five years. Doesn’t change oil analysts significantly, but does catch significant amount of extremely fine ferrous metal particles which are not caught by full flow filter. Has to be better than having extra debris circulating in oil.

AM365 3.5 Aeromag Oil Filter Magnet

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Aircraft Spruce Canada

Aircraft Spruce Canada