1-877-795-2278 | info@aircraftspruce.ca

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

THE AVIATION SUPERSTORE FOR ALL YOUR AIRCRAFT & PILOT NEEDS | 877-795-2278

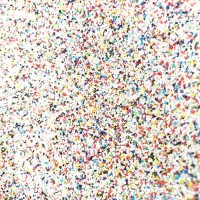

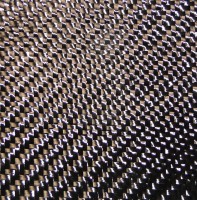

Bidirectional Woven Lumat Aramid - 4 Harness Satin Weave 1500D

$57.75/Yard

Part# 01-01665

MFR Model# F-2506-50

MFR Model# F-2506-50

- JUMP TO

- Overview

- Spec Chart

- Reviews

- Q&A

- View in Catalog

Overview

|

**Note: These products are sold by the yard** The resin consumption provided is for the approximate amount of resin by weight, contained in the final part after processing by vacuum infusion. This does not account for the resin used in the flow lines and consumables such as flow media or breather cloth. Wet-layup by hand will also have a higher resin consumption in the final part and is dependent upon users techniques. Vacuum bagging a wet layup will improve the resin content. Too much resin will cause a weaker part, NOT stronger. Average rule of thumb is around 45% (+/- a couple percent). To calculate actual resin % in your part a burn test is used. For example you have a part weighing 100 grams, you would burn off the resin which would leave the fiber behind. You should have 55 grams of fiber left when your process is working correctly. Due to the variables in processing it is hard to give an accurate amount of resin needed to purchase for making your part. However you will have waste no matter what method is used. A suggested ratio is about 1-1.5lbs of resin per lb of fabric purchased. |

Spec Chart

| Unit of Measure | Linear Yard |

|---|---|

| Material Warp | Aramid |

| Material Weft | Aramid |

| Weave | 4 Harness Satin |

| Ends Per Inch | 13 |

| Pics Per Inch | 13 |

| Yarn Size Warp | 1500d |

| Yarn Size Weft | 1500d |

| Tow Size | 1500d |

| Weight | 5oz/170gsm |

| Width | 50"/127cm |

| Thickness | |

| Resin Consumption @ 45% Resin to Fabric by Weight | 4.09opsy/137gsm |

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Aircraft Spruce Canada

Aircraft Spruce Canada