Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

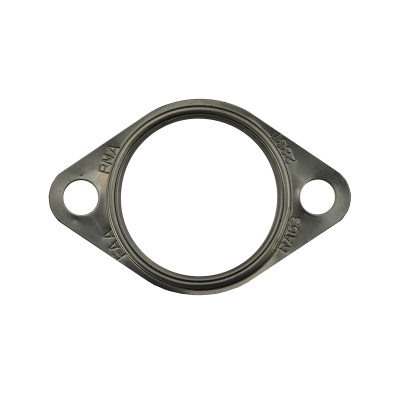

Short Sleeve Rapco Exhaust Gasket RA632837

MFR Model# RA632837

- JUMP TO

- Overview

- Reviews

- Q&A

- View in Catalog

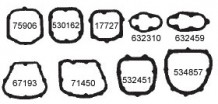

| Description | Part Number |

|---|---|

| Cont.#21493 for A-65 to 0-300 | 08-05237 |

Overview

| Continental P/N 21493 (now P/N 632837 stainless steel) |

Reviews

Short Sleeve Rapco Exhaust Gasket RA632837

INEXPENSIVE

Short Sleeve Rapco Exhaust Gasket RA632837

2 stacked per flange

Short Sleeve Rapco Exhaust Gasket RA632837

These are stamped sheetmetal and youll want two for each cylinder. For best results, use them with the concave sides together with a wee bead of red RTV between them. then another wee bead of red RTV on each outer side of the sandwich, to ensure a very good seal between the head and the manifold.

Short Sleeve Rapco Exhaust Gasket RA632837

Working OK.

Short Sleeve Rapco Exhaust Gasket RA632837

Short Sleeve Rapco Exhaust Gasket RA632837

Works well.

Short Sleeve Rapco Exhaust Gasket RA632837

Good Quality from Rapco

Short Sleeve Rapco Exhaust Gasket RA632837

Good product, for the Continental GO 300 E are necessary 2 gaskets per exhaust, so 6 cilíndrese 12 gaskets.

Short Sleeve Rapco Exhaust Gasket RA632837

just the right part for my O300.

Short Sleeve Rapco Exhaust Gasket RA632837

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Only one of the RA632837 gaskets are required per cylinder. The RA630365 have a raised bead that can be stacked if desired, but not required

This is used as one per cylinder.

Per Rapco: It is recommended that all exhaust gaskets, flat and spiral wound, are changed each time they are removed. They are designed to crush into place to block high temperature exhaust gases from eroding any uneven mating surfaces. If reused they may not seal properly.

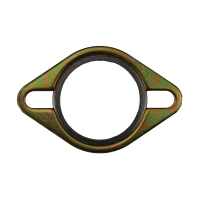

Make sure cylinder and exhaust stack flanges are flat. Check aircraft maintenance manual for proper installation. In most cases solid gaskets should be installed in pairs with raised beads interlocked and facing away from the cylinder. Also check maintenance manual for exhaust nut torque spec. Re-torque after a hot run.

2.25" od, 1.765" id, .05 thick, 2.5" hole center to hole center.

Aircraft Spruce Canada

Aircraft Spruce Canada