Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

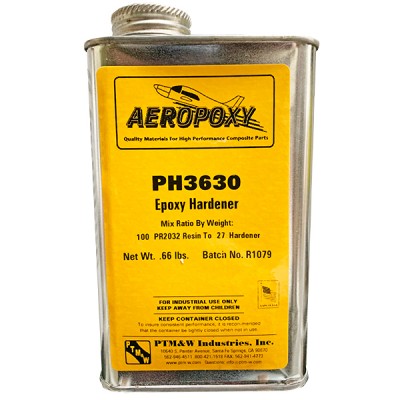

Aeropoxy PH3630 Hardnr 1 Pint

MFR Model# PH3630

- JUMP TO

- Overview

- Documents

- Reviews

- Q&A

- View in Catalog

| Description | Quantity | Pot Life | Part Number |

|---|---|---|---|

| PH3630 Hardener | Pint | 30 Minutes | 01-00160 |

Overview

|

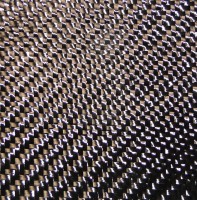

PR2032 is a medium viscosity, unfilled, light amber laminating resin that is designed for structural production applications. Three hardeners are available for use with PR2032. PH3660, has a 1-hour pot life. When used with either of these hardeners, the system gives excellent wet-out of fiberglass, carbon and aramid fibers. Special additives have been incorporated into this system to promote chemical adhesion to fabrics made with these fibers. The AEROPOXY systems will cure completely at room temperature, or can be given an elevated temperature cure. AEROPOXY contains no MDA (a known liver toxin and carcinogen) and meets or exceeds current OSHA requirements for safe use. It satisfies all structural, pot life and wet-out characteristics according to tests by Rutan Aircraft Factory, and RAF recommended its use for all homebuilt aircraft applications. The best ratio on AEROPOXY is 100:27 by weight or 3 to 1 by volume. In early 1996 several improvements were made to AEROPOXY. The viscosity was lowered for easier laminating, the occasional slight surface tackiness in high humidity was eliminated, the AEROPOXY hardeners were modified to prevent any tendency to crystallize in high humidity, and the mix ratios were modified to an exact 3 to 1 by volume. |

Documents

- Tech Data Sheet (PDF)

- PH3660 Safety Data Sheet (PDF)

- PH3665 Safety Data Sheet (PDF)

- PH3630 Safety Data Sheet (PDF)

- PR2032 Safety Data Sheet (PDF)

Reviews

So far so good. I used it for the first time recently and it has met every expectation. Viscosity is low so it spreads similar to house paint, perhaps a tad thinner (at temperature of about 65 degrees). Probably would run thinner at higher temps. Unfortunately, it is fall here and my workshop stays cool (55-60 degrees F) so it has been over 35 hours and it is still slightly tacky. My only complaint is the containers, and getting the stuff out into a measure cup. It gets messy because it’s hard to pour without spilling. Anyone know it there is a pour spout for these qt cans??? That would help. Otherwise, 5 stars.

Have not opened this one yet, but I suspect it is actually 1/3 qt vs a full pint, which is fine, as you dont need any more to mix with a quart of resin.. Same comment: i.e. description should say 1/3 qt if that is what it is..

Aeropoxy PH3630 Hardnr 1 Pint

Im coming to love AeroPoxy. Im building a Cozy with MGS epoxy for the structure and West epoxy for finishing and non-structural odd jobs. I decided to do the wheel pants in AeroPoxy and got great performance. The product penetrates well, making for good layups, and cures nice and hard. Where cured West layups will still delaminate, the AeroPoxy locks on. The gallon kit is affordable and ACS brought it to Sun-N-Fun for free.

Order was shipped quick and packaging was great

This Product should be kept fresh for the Consumer, It had settled out, and needed to be stirred

This is the greatest laminating epoxy. I use it for its high temperature capabilities.

My favorite laminating epoxy. Excellent wetout properties, great pot life and I have never had an exotherm, even with very thick layups.

Quality resin and low odor.

I use this epoxy and use a Harbor Freight scale to measure out the ratio by weight. I am not experienced at composite, and have not had any failures using this. But at 50F it takes a long time to cure....week? It did cure though!! A system that uses pumps has waste. With s small digital scale I can measure our 5 grams, or 50g. If you choose to use a pump measuring system you lack that versatility, and will increase your cost due to waste. I only gave it 4 stars because I dont have much experience with other types. I have used West System and also like it.

No pumps screw onto the port. They expect you to attach a spout and heave this thing on its side to have a controlled pour. Not spigot a spout. That was the recommendation from the manufacturer.

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

24hr, at room temp, is recommended. Heat can be applied to accelerate the cure time. Please see the Tech Data Sheet under the "Documents" tab for more info.

They do not come with pumps but you can use the west system pumps on the Aeropoxy kit. P/N# 01-00318.

Acetone is commonly used for cleaning un-cured epoxies. We also have Replacetone, 01-08823, which is a non-haz cleaner for un-cured epoxies.

As long as the hardeners have the same ratio they can be blended. 3630/3660/3665 are all 100:27.

Yes, this is safe to use with closed-cell polystyrene foam.

Aircraft Spruce Canada

Aircraft Spruce Canada