Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

| Description | Quantity | Pot Life | Part Number | Price | Buy |

|---|---|---|---|---|---|

| PR2032 Resin | Quart | - | 01-42125 | $82.75 | |

| PR2032 Resin | 3/4 Gallon | - | 01-42140 | $218.95 | |

| PR2032 Resin | 5 Gallon | - | 01-42155 | $1085.00 | |

| PR2032/PH3660 Kit | Quart Kit | 1 Hour | 01-42135 | $122.75 | |

| PR2032/PH3660 Kit | Gallon Kit | 1 Hour | 01-42150 | $325.00 | |

| PR2032/PH3660 Kit | Pail Kit | 1 Hour | 01-42165 | $1441.00 | |

| PH3630 Hardener | Pint | 30 Minutes | 01-00160 | $39.80 | |

| PH3630 Hardener | Quart | 30 Minutes | 01-00161 | $96.75 | |

| PH3660 Hardener | Pint | 1 Hour | 01-42130 | $39.80 | |

| PH3660 Hardener | Quart | 1 Hour | 01-42145 | $107.75 | |

| PH3660 Hardener | 2 Gallon | 1 Hour | 01-42160 | $428.00 | |

| PH3663 Hardener | Pint | 90 Minutes | 09-05266 | $36.70 | |

| PH3663 Hardener | Quart | 90 Minutes | 09-05267 | $107.75 | |

| PH3663 Hardener | 2 Gallon Pail | 90 Minutes | 09-05268 | $506.00 | |

| PH3663 Hardener | 30-Gallon Drum | 90 Minutes | 09-05269 | $2945.00 | |

| PH3665 Hardener | Pint | 2 Hours | 01-00162 | $39.80 | |

| PH3665 Hardener | Quart | 2 Hours | 01-00163 | $105.75 |

- JUMP TO

- Overview

- Documents

- Reviews

- Q&A

- View in Catalog

Overview

|

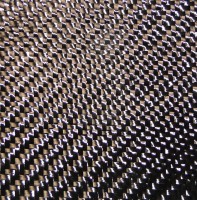

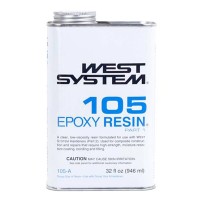

PR2032 is a medium viscosity, unfilled, light amber laminating resin that is designed for structural production applications. Three hardeners are available for use with PR2032. PH3660, has a 1-hour pot life. When used with either of these hardeners, the system gives excellent wet-out of fiberglass, carbon and aramid fibers. Special additives have been incorporated into this system to promote chemical adhesion to fabrics made with these fibers. The AEROPOXY systems will cure completely at room temperature, or can be given an elevated temperature cure. AEROPOXY contains no MDA (a known liver toxin and carcinogen) and meets or exceeds current OSHA requirements for safe use. It satisfies all structural, pot life and wet-out characteristics according to tests by Rutan Aircraft Factory, and RAF recommended its use for all homebuilt aircraft applications. The best ratio on AEROPOXY is 100:27 by weight or 3 to 1 by volume. In early 1996 several improvements were made to AEROPOXY. The viscosity was lowered for easier laminating, the occasional slight surface tackiness in high humidity was eliminated, the AEROPOXY hardeners were modified to prevent any tendency to crystallize in high humidity, and the mix ratios were modified to an exact 3 to 1 by volume. |

Documents

- Tech Data Sheet (PDF)

- PH3660 Safety Data Sheet (PDF)

- PH3665 Safety Data Sheet (PDF)

- PH3630 Safety Data Sheet (PDF)

- PR2032 Safety Data Sheet (PDF)

Reviews

PR2032/PH3660 Quart Kit

PH3660 Hardener Pint

PR2032/PH3660 Quart Kit

Good product

PR2032/PH3660 Quart Kit

Excellent product.

PR2032/PH3660 Quart Kit

Nice and fresh product

PH3660 Hardener Quart

Nice and fresh product

PR2032 Resin 3/4 Gallon

Consistent product. Double bagged for shipment prevents spillage from occurring and damaging other products

PR2032 Resin 3/4 Gallon

PR2032 Resin Quart

The product is fine and does what its supposed to do. Read the description as a pint can doesnt have 16 fluid ounces. This is as packed by the manufacturer, not an ACS caused problem...

PH3660 Hardener Pint

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

24hr, at room temp, is recommended. Heat can be applied to accelerate the cure time. Please see the Tech Data Sheet under the "Documents" tab for more info.

They do not come with pumps but you can use the west system pumps on the Aeropoxy kit. P/N# 01-00318.

Acetone is commonly used for cleaning un-cured epoxies. We also have Replacetone, 01-08823, which is a non-haz cleaner for un-cured epoxies.

As long as the hardeners have the same ratio they can be blended. 3630/3660/3665 are all 100:27.

Yes, this is safe to use with closed-cell polystyrene foam.

Aircraft Spruce Canada

Aircraft Spruce Canada