Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

Aeropoxy Structural Adhesive - ES6209 - Quart

MFR Model# ES6209 A/B

- JUMP TO

- Overview

- Tech Data

- Reviews

- Q&A

- View in Catalog

Overview

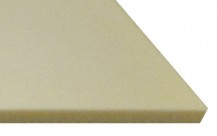

| ES6209 is a translucent, straw colored two component epoxy adhesive with a thick, liquid consistency. ES6209 is an excellent structural adhesive for use when good flow and surface wetting are required. Though pourable it has a controlled flow viscosity to minimize run-out from the adhesive joint. The 1 to 1 combining ratio by weight or volume makes it easy to measure and mix. The working time of over an hour provides plenty of time to coat and assemble the materials to be bonded. ES6209 has excellent adhesion to composite and metal parts typically used in kit plane construction. It bonds rigid foam, wood, ceramics, fiberglass and most metals with ease. When the ES 6209 is cured it provides tough, durable structural joints. Mix Ratio: 1 to 1 by weight or volume; Color: Translucent Amber, Mixed Viscosity: 45,000-55,000cps; Pot Life 4fl. oz. Mass: 60-90 min @ 77°F; Cure Time @ 77°F 18-24 hrs, @ 140°F 2-3 hrs. |

Reviews

Aeropoxy ES6209 Quart A/B

excellent. worked worked just as advertised

Aeropoxy ES6209 Quart A/B

Item was as expected and was delivered promptly. I have been using this epoxy for nearly 20 years. Its the best for plywood, fiberglass, and aluminum.

Aeropoxy ES6209 Quart A/B

Product good stuff but the description is wrong. The resin in NOT straw coloured, it is a light milky white colour. The hardener is a very dark amber. I transferred amounts into squeeze bottles (then labelled them) to make it easier to portion. When mixed, it has the consistency of thick ketchup - thicker is better for my needs.

Great epoxy. Can use west system 300 pump to measure out precise equal “volume” amounts. End product stays usable for a couple hours. Does take almost a day to cure cause I am building my project in a relatively cool basement.

I used this epoxy for the construction of a high power rocket (L2), and it worked extremely well! Just have a plastic container/cup and something to stir with ready.

Works as advertised. Only thing to note is that per the manufacturers data sheet, this is sold by weight (1.75 lbs each.) Upon opening the cans they are less than full (one appeared about 2/3 full) however both cans weigh 2 lbs. Since the volumes are different, it would be prudent to mix these by weight rather than volume even though the data sheet indicates that either method can be used.

Great structural resin for rocketry projects!

I use it for building high-power rockets where strength is critical -- thrust rings, through-the-wall fins, shock cord attachments, etc. Slow cure with minimum out-flow, its perfect for laying in fillets on the fin-to-airframe joint.

After testing several epoxy products for farm and family, then using this epoxy over a ten year period on numerous many materials, the ES6209 Aeropoxy has yet to fail. Nothing compares. Resulting joint appears to remain in a non-brittle state after years of placement. Make sure all surfaces are fully saturated before assembling with clamping. Excess glue is easily removed with hand tools clean to joint, if desired, after hardening overnight.

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

This adhesive is in a quart container. We have since added this info to the title of the webpage.

The ES6209 works very well, but the ES6228 is designed for metal bonding and would work better. We have added the ES6228 as an "Alternate Item" to this web page. Please check the "Alternate Items" tab for a link to that web page.

This product is sold as a kit, both parts A and B will be included with part # 01-00295.

1 year from the date of shipment.

The pot life at 77 degrees F is 60-90 minutes.

The west system pumps (01-00318) will dispense the epoxy from these cans. The ratios would not be correct but these would pump from the cans.

This is not fire retardant.

Quart is the smallest size available for the ES6209.

Per Vendor: "Most of these room temperature epoxies are good to about 150F. If they want to use them at temperature, a cure is advised before just putting them into service. If they need higher capacity than that, let me know."

Aircraft Spruce Canada

Aircraft Spruce Canada