Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

West System Six10™ Thickened Epoxy Adhesive Cartridge - 190 Ml

MFR Model# 10287571

Overview

|

Epoxy bonds incredibly well to woods, fiberglass materials, metals, and concrete, but it is typically a two-part system that requires mixing cups, stir sticks, pumps, fillers, and other equipment and can be intimidating to some users. West System has always aimed to make using epoxy easier; Six10® is the result of this pursuit and effectively takes the intimidation out of bonding with epoxy.

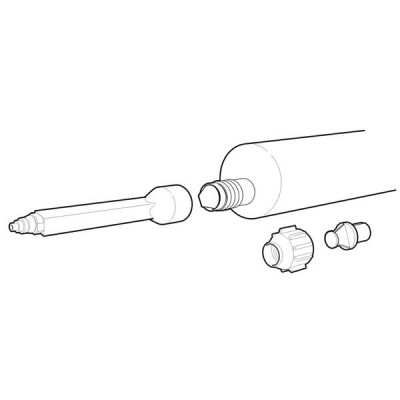

Six10® uses a unique tube with separate chambers for epoxy resin and hardener. As both components exit the tube they mix in a static mixing nozzle and are ready for application as they exit the nozzle opening; simply apply epoxy as you would caulk. Six10® has a working time of 42 minutes (within the static mixer) so it can be used for a wide variety of projects. The epoxy is pre-thickened to prevent sagging during the curing process. As the epoxy is mixed or spread, it will thin slightly and can be used to wet out moderate weight fiberglass or carbon fiber. The initial cure is achieved in 5-6 hours. If you only need a little amount of epoxy, squeeze out what is needed then remove and dispose of the static mixer and cap the tube. The separation of the resin and hardener allows Six10® to be stored for later use. Additional static mixers can be purchased separately in sets of two or by the dozen for later use. Remove some of the stress of working with epoxy by using Six10® cartridges with a static mixer and caulking gun convenience for your next bonding project. |

Features

- Easy to use cartridge with static mixer

- Ideal for bonding applications and wetting out moderate weight fiberglass and carbon fiber

- Designed to balance properties of 105 resins with G-Flex flexibility

- Unique two chamber tube allows storage of an opened tube

- Additional static mixers available in two or twelve packs (sold separately)

Specifications

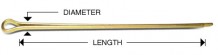

| Capacity | 6.46 Ounces Cartidge |

|---|---|

| Color | Clear |

| Cure Time | 5 to 6 Hours |

| Material | Two-Part Epoxy |

Documents

- Technical Data Sheet (PDF)

- Safety Data Sheet (PDF)

Videos

Reviews

The epoxy itself works great. The problem I had was with the applicator tip. It stopped with only about a quarter of the epoxy out of the tube. Had to take it off and just mix it by hand on a board. Trying to use it in a hand calking gun is almost impossible. I have used this epoxy a lot and every time I have used it it is the same. Works great but just dont expect it to come out of the tube like it is supposed to.

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Aircraft Spruce Canada

Aircraft Spruce Canada