Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

Instrument Mounting Nut A8942-632-493

- JUMP TO

- Overview

- Reviews

- Q&A

- View in Catalog

| Obsolete Part No. | Our Part No. | NAS Parts No. | Instrument Thickness |

|---|---|---|---|

| A8942-632-493 | MS33737-14C | 487-18 | .313 |

Overview

|

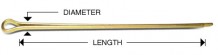

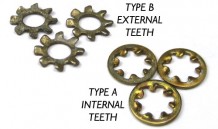

Cage type. Permit mounting of aircraft instruments from

the front of the panel. No charge in panel or instrument design required. Non-magnetic (speed nut is brass; cage is phosphor bronze). Conform to MIL-N-3336. Cage is easily compressed with finger-pressure to allow insertion of legs into clearance holes. When fully inserted and pressure is released, legs spring apart; retain SPEED NUT in screw-receiving position. Turned down corners hold firm against force of in sert ing screw and screw-tightening torque. All instrument mounting nuts listed below take a 6-32 machine screw. Additional Info: the thread size is the same on each nut, but the instrument bezel thickness can be different per gauge. They are ordered by the back bezel thickness. They are inserted from the back, and they have ears pointing out that slide into a groove between the front and back bezel to stay in place. |

Reviews

very good product

Instrument Mounting Nut A8942-632-493

they work.

Pefect for those mounting nuts that fall off in the back of the instrument panel when replacing/removing instruments. Excellent directions and sizing instructions given by AS&S.

OK

I knew what I wanted and that’s what I got.

Great item that can save many hours of frustration compared to trying to thread a traditional nut. Well worth the money.

This type of hardware design is under appreciated. always provides good instrument mounting.

Absolutely do not work , the picture shows a pronounced bend at the tip where it would grip in the bezel. The actual part does not have that bend or it is so tiny that it is difficult to see. The clips fall out when trying to install and if I do get it in place , trying to start the screw will push the clip out. Yes , they is long enough, they are the longest offered and trying to install a turn coordinator.

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Aircraft Spruce Canada

Aircraft Spruce Canada