1-877-795-2278 | info@aircraftspruce.ca

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

SAME DAY SHIPPING ON ORDERS PLACED BY 2 PM | 877-795-2278

- JUMP TO

- Overview

- Features

- Applications

- Reviews

- Q&A

Overview

|

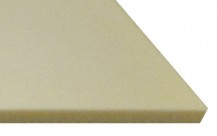

FR-3700 meets the requirements of aircraft BMS 8-133. This rigid, polyurethane foam is comparable to the FR-6700 in strength, temperature resistance and flammability performance. However, the FR-3700 is tougher (less friable) for cutting crisper edges.

FR-3700 is a CFC-free, rigid, closed-cell, flame-retardant polyurethane foam available in densities ranging from 3 to 40 pounds per cubic foot. It exhibits a high strength-to-weight ratio due to its cellular structure and cross-linked resin. Because of its closed-cell structure, LAST-A-FOAMŪ FR-3700 has great resistance to water absorption, and will not swell, crack, or split on exposure to water. This series is non-abrasive and can be machined with standard high-speed steel (HSS) cutting tools. It can also be cut cleanly with water jets and traditional wood-carving tools. This flame-retardant polyurethane (PU) foam particularly supports the following industries. |

Features

- Stable and inert

- Flame retardant

- High strength-to-weight ratio from cross-linked resin

- Resistant to most chemicals and solvents

- Easily shaped with common woodworking tools

- Performs well as wood replacement

- Will not support fungal growth

- Max use temperature of 260°F (127°C)

Applications

- Models and design prototypes

- Composite core, especially where flame retardation is important

- Honeycomb edge closeout for aircraft interior sandwich panels used in overhead storage bins, passenger cabin class dividers, galleys and lavatories

- Radioactive materials (RAM) transportation packages

- Impact- and fire-insulation liner for hazardous waste containers

- Vacuum form dies and mold patterns

- Artificial human bone test media

- Core material for composite prostheses

- Load bearing

- Dielectric material for radomes and antennas

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Aircraft Spruce Canada

Aircraft Spruce Canada