Aircraft Spruce Canada

Brantford, ON Canada

Corona, CA | Peachtree City, GA

Chicago, IL | Wasilla, AK

Vacuum Bagging Techniques

MFR Model# 542662

- JUMP TO

- Overview

- Documents

- Reviews

- Q&A

- View in Catalog

Overview

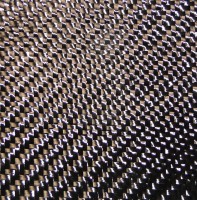

| Vacuum bagging is a composite materials processing method that produces higher quality laminates by eliminating voids, removing any extra resin, and conforming the materials to shapes more effectively. The weight of the laminate can be reduced without compromising strength by removing excess resin that cannot be removed during basic hand lay-ups. Eliminating voids in the laminate produces much better strength and helps eliminate potential failure points. Vacuum bagging is more expensive and time consuming than hand lay-ups, but can offer superior strength and substantial weight savings in laminates. The following materials provide all the basic components necessary for vacuum bagging. |

Documents

Reviews

I was expecting to get the original booklet, but I got a zerox copy...pictures were fuzzy and hard to see detail.

Q&A

Please note, Aircraft Spruce Canada's personnel are not certified aircraft mechanics and can only provide general support and ideas, which should not be relied upon or implemented in lieu of consulting an A&P or other qualified technician. Aircraft Spruce Canada assumes no responsibility or liability for any issue or problem which may arise from any repair, modification or other work done from this knowledge base. Any product eligibility information provided here is based on general application guides and we recommend always referring to your specific aircraft parts manual, the parts manufacturer or consulting with a qualified mechanic.

Aircraft Spruce Canada

Aircraft Spruce Canada